The Cutting Edge in Sorting Technology and Harvester Improvement

By Wei Yang, OSU Blueberry Specialist

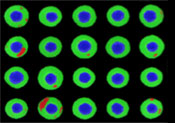

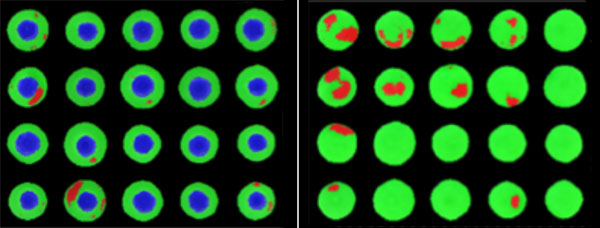

Blueberry fruit often gets damaged internally during machine harvesting. The detection of such internal bruising damage (IBD) is challenging because the internal bruises are hidden from sight. When the fruit are bruised internally, free water is released from cells of damaged tissue under the blue peel, creating differences in optical properties between bruised and healthy tissues. More free water in damaged tissue absorb more light at certain wavelengths than healthy tissues. In the near-infrared (NIR) wavelength range of 970-1400 nm, hyperspectral transmittance imaging detected that bruised tissues have higher light transmittance intensities than healthy tissues, resulting in clear separations between damaged and healthy tissue for a single berry at difference viewing positions. It was recently discovered that the largest difference between the spectral intensities of bruised and healthy tissue was at around 1070 nm wavelength (Fig.1). Therefore, sorting equipment using the wavelength in the NIR range shall greatly improve the accuracy of sorting out fruit with internal bruising damage.

|

| Fig. 1. Fruit image under a hyperspectral transmittance camera using 1070 nm wavelength. Red color indicates bruised tissues, green color for healthy tissues, and blue color for calyx center. |

In the 2018 growing season in Oregon, a fixed hyperspectral transmittance imaging (using 1070 nm) camera was used to detect fruit IBD after sorting. Our study found that ‘Duke’ blueberry harvested by machine had only 30% fruits with no IBD at all, 58% fruits have IBD between 0.1-10%, 8% fruits have IBD between 10-20%, and 4% fruits have more than 20% IBD. These results indicate that sorting did not remove some fruits with significant IBD at more than 10%. Fruit with significant IBD usually became soft after one week in cold storage and have a shorter shelf life. The improvement in sorting technology, especially using NIR imaging, is needed to increase the efficacy of sorting out the IBD fruit.

With the OBC support, Oregon Department of Agriculture has funded a two-year Block Grant for us to continue developing of a modified fresh blueberry harvester. Design changes in using soft materials on the over the row (OTR) machine harvester to reduce fruit IBD has showed promise in our previous studies. Multiple harvesting experiments with a modified OTR harvester from Oregon and Washington in 2018 demonstrated that fruit firmness and pack out equal or are comparable to hand harvested fruit and better than standard OTR harvested fruit. Fruit IBD was also significantly reduced with soft materials on the OTR. The advances in the OTR harvester design along with better sorting technology will bring the machine harvesting for fresh blueberry ever closer to reality.

| SPRING 2019 |